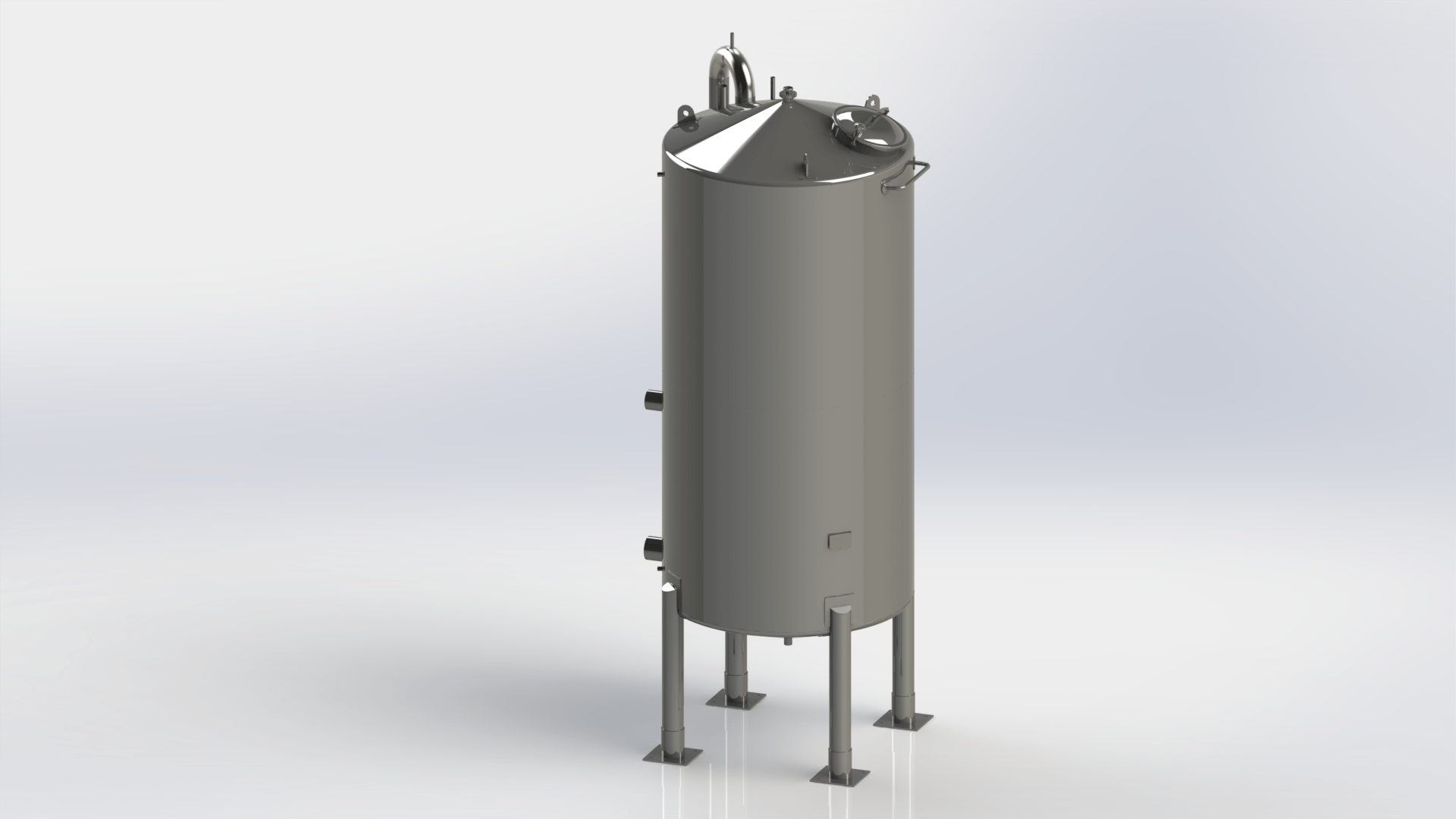

CIP TANKS

Clean-in-Place installations enable automatic sterilization of the entire system without the need for disassembly or personnel intervention. They are used in a variety of industries.

ENABLE AUTOMATIC

STERILIZATION

Clean-in-Place (CIP) is a method of automatic sterilization of the entire system and cleaning the interior surfaces of pipes, vessels, equipment, filters, and associated fittings without disassembly or personnel intervention. CIP is frequently applied to equipment such as piping, tanks, and fillers.

Our CIP vessels can be used in the following applications:

Pharmacy and cosmetics;

Beer production;

Production of juices and other soft drinks;

Milk processing;

Production of alcohol and alcoholic beverages.

WHY CHOOSE US

WE PROVIDE MORE THAN HIGH-QUALITY STAINLESS STEEL PROCESS EQUIPMENT

We are committed to both service and production and want to provede the best customer support at all times. Our dedicated team offers competent advice in all areas - from the preliminary project planning, design and production to scheduling, assembly and transportation. This allows us to ensure that our service exceeds your expectations.

PRODUCTS VARIETES

CIP TANK

CIP TANK

CIP TANK

FRESH WATER TANK

CIP TANK

CIP TANK 1500 L

CIP TANK ATOMIZER

SERVICES

In collaboration with our customers, Ambyx develops solutions that incorporate state-of-the-art technology and align with industry trends and standards.

We also offer support with product installation, assembly, and transportation. Our expertise is well-recognized in the industry, and we’d be pleased to provide you with guidance!

2D and 3D Design

Installation and Assembly

Inspection and Supervision

QUALITY & CERTIFICATES

Ambyx provides strict quality control in order to ensure the delivery of a safe and high quality products. Compliance with the international standards helped us earn the trust of the market leaders in the industry.

ISO 9001:2015

ISO 3834-2:20064

AD 2000-Merkblatt HP0

ASME

OUR CLIENTS

Our clients are one of the world’s largest systems suppliers for the food, beverage, and Pharmaceutical sectors. They have extensive expertise in the concentration of liquids in the Chemical, Pharmaceutical, and Food industries. They are suppliers of industrial drying solutions, including dewatering and evaporation equipment, from R&D-scale and standalone equipment to fully integrated production lines and continuous manufacturing systems. And provide individual and tailor-made solutions for the beer, beverage, and liquid food industries from a single source.